'Significant capacity expansion through automation.'

Van Leeuwen Czech Republic

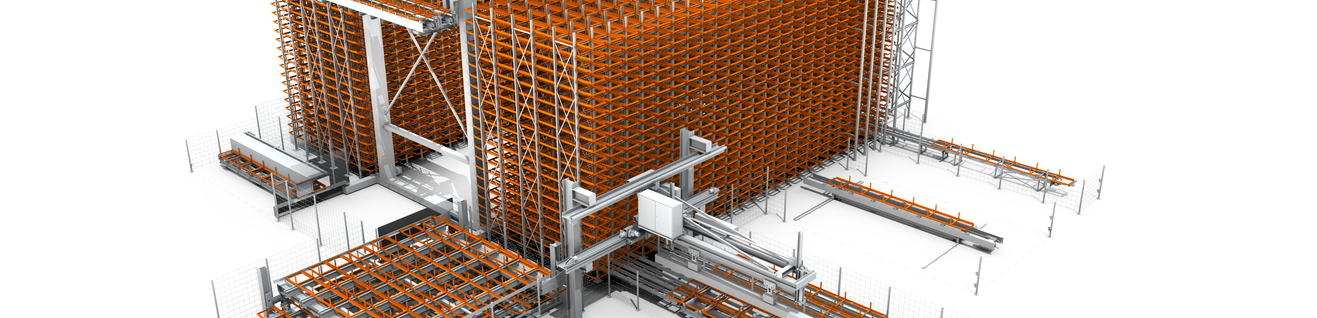

Last year, Van Leeuwen Czech Republic invested in an upgrade of the Exactcut cutting line by acquiring a new bundle feeder and a robot arm. The bundle feeder ensures that the cutting line is loaded one pipe after the other. The robot arm takes the product from the conveyor, moves it to the cleaning unit and then places the pipe in the appropriate pallet box. Employees then prepare the full box for packaging or shipment. This has significantly increased output. In addition, in 2018, Van Leeuwen Czech Republic made preparations for its next major investment: the construction of a new 4,320 m2 hall with room for the flexible, modular KASTO warehouse management system. With this innovative crane and storage technology we achieve high efficiency and greater safety. Hans Zondervan, General Manager Van Leeuwen Czech Republic: ‘The automated KASTO high-rise warehouse makes it possible to expand our capacity despite the extremely tight Czech labor market. In the near future we will be able to transport the right materials five times faster to the picking, packaging or cutting station. Searching for the right storage location and fetching the materials will then be a thing of the past. This automation leaves us with more time and room for processing the more specialized orders, which is something that Van Leeuwen Czech Republic would like to focus on.’